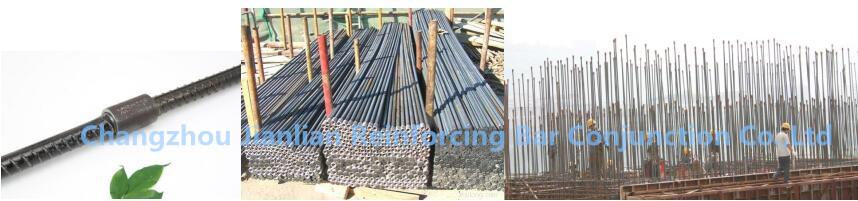

JB-2000 Type steel bar parallel thread upset forging standard type

From 2006 until now, the champion of sales machine,annual production capacity is 300 sets.

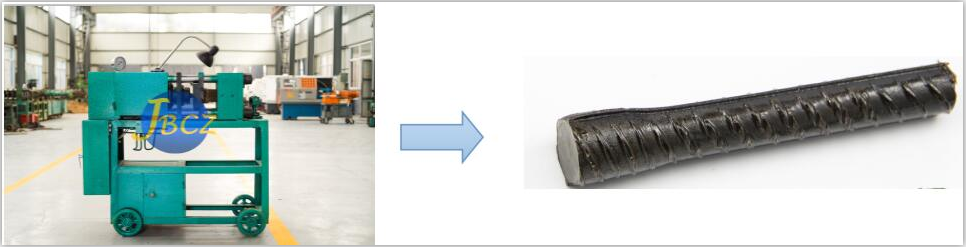

1. Rebar end upset forging machine

First step, Cold forging the end of rebar , the principle of enlarge the end of rebar , I Make the molecular structure more tight, II enlarge the cross sectional area of rebar (These two design principle make the tensile strength of rebar end more stronger)

The machine process the rebar diameter range: from 12mm to 40mm

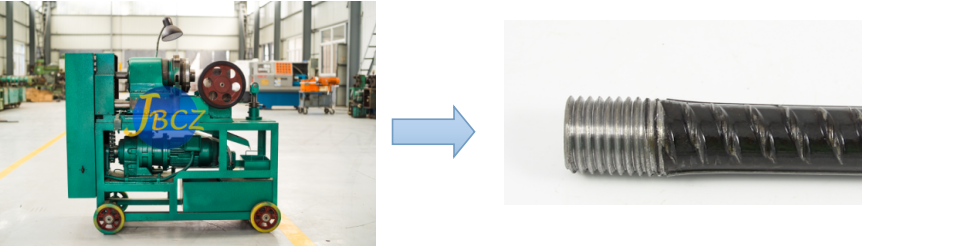

2. Rebar threading machine

Make thread on the end of rebar which has been enlarged, the thread size matches rebar coupler connection, the range of machine processing rebar: 12mm-40mm

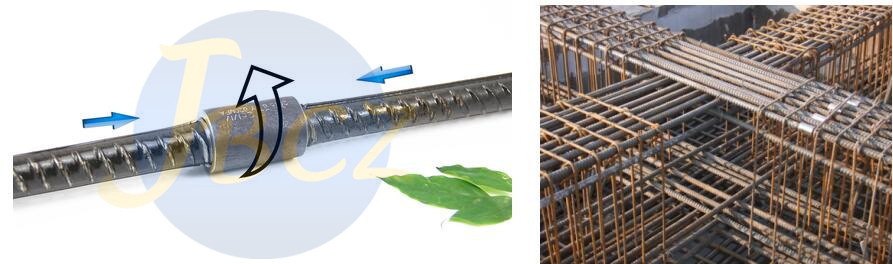

3. Process the thread well, finish two steel bars connection within 30 seconds.

Using rebar coupler with upset forging parallel thread.

Using rebar coupler with upset forging parallel thread.

4. Test result: JBCZ upset forging parallel thread connection is 100% higher than steel bar material strength , rebar connection belongs to the world’s highest standard requirements, satisfy: American ACI-318, AC-133 cyclic test, ICC-ES, type 2, British BS4449, UK CARES, TA1-A, TA1-B, France AFCAB, ISO15835, DCL approval, Slip test and other world’s highest quality inspection.

After finishing rebar connection, the tensile strength is 700-1050MPA, yield strength is 500-800MPA.

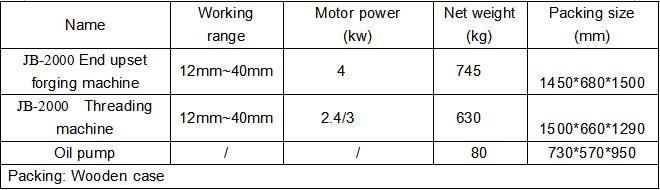

Machine specifiaction table :

The cross sectional area of upset forging parallel thread is

bigger than rib peeling Roll thread obviously.

Please check the comparison diagram, the molecular structure of upset forging reinforcement is more compact,

and cross sectional area is bigger, in order to strength

the tensile strength of joint. The tensile test of upset forging parallel thread is 100% higher than

steel bar raw material, please check the test picture.

I There are many types of connection , satisfy each connection request on job site:

Standard type, this connection type is suitable for 80% projects. Our products can applied to bridge rebar splice, Nuclear power engineering rebar splice, Seawater desalination rebar connection, LNG project rebar splice, Metro rebar connection, High tower rebar connection, Viaduct rebar connection and etc.

II.Reducing rebar coupler connection, suitable for the change between story , for example , the basement adopt 32mm rebar , the story use 25mm rebar , it need reducing coupler in this situation ,

one end connect 32mm , another end connect 25mm , satisfy rebar connection in different sizes.

III.Adding length coupler connection , this type of connection suitable for the situation that two reinforcing bars can’t be rotated , such as the rebar cage connection at job site ,

both of the rebars can’t be rotated, then this type of connection is the most suitable one.

First step , screw the full coupler onto the first bar

Second step , screw back the coupler onto the second bar

Third step , finish the connection

Ⅳ.Left and right hand coupler connection , this type is suitable for the project that two rebars or one rebar can’t be rotated , the advantage is only need to rotate the coupler can finish the connection of two rebars.

One end of rebar thread is right hand , the other end of rebar thread is left hand , the rebar thread match with coupler, tighten two rebars while rotate the coupler , the coupler size : 12mm to 40mm rebar connection range.

Ⅴ.Adding length with nut connection , it is the same principle as adding length coupler connection , suitable for connecting two reinforcing bars which can’t be rotated, use the nut to fix the coupler make it can’t move up and down.

Ⅵ.Terminal coupler connection , this type is suitable for the embed project such as embedded column, wall embedded, all need this type , during the embedded , in order to prevent the concrete poured, each coupler will with one plastic cover to protect the thread of coupler . Product size satisfy : 12mm to 40mm rebar connection range.

VII.Terminal coupler connection , this type is suitable for the embed project such as embedded column, wall embedded, all need this type , during the embedded , in order to prevent the concrete poured, each coupler will with one plastic cover to protect the thread of coupler . Product size satisfy : 12mm to 40mm rebar connection range.

VIII.Half thread half press coupler connection , this type connection is suitable for the situation that one end of rebar has already poured into concrete and can’t be rotated. Product size satisfy: 12mm to 40mm rebar connection range.

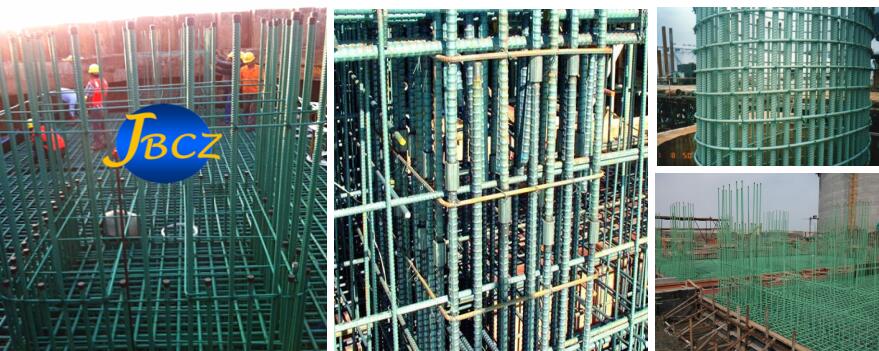

VVI.Epoxy coated rebar connection . Epoxy couplers have been applied in the world’s first longest bridge—Hangzhou Bay Crossing Sea bridge , The world’s second largest water pump station in Jeddah , Saudi Arabia.

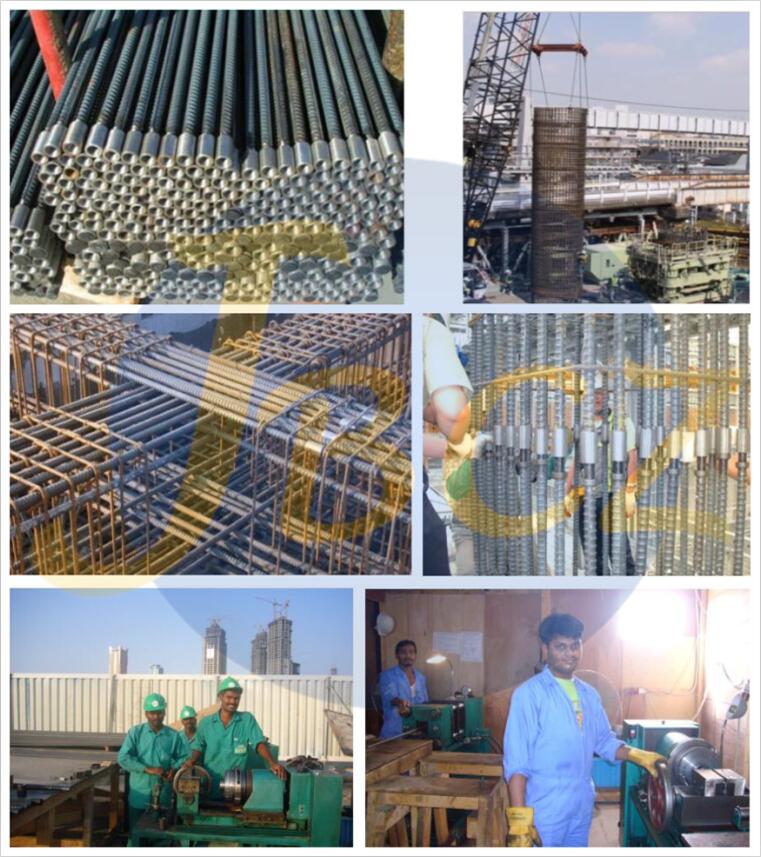

Real application pictures in rebar thread job site.