Bartec type —Upset forging parallel thread rebar splicing coupler

Cold forging connection system

Cold forging connection system

Product Feature

Bartec type rebar coupler is parallel thread splicing system which is designed for Ø12 to Ø40mm(ASTM #4 to #8)rebar conneciton. Designed and produced in compliance with Eurocode 2, BS 8110, DIN 1045, ACI 318, IBC, AASHTO, ASME Sec III Div 2

Product advantage

*No reducing of rebar cross sectional area

*Pass elongation test .

*Easy installation , no need torch wrench.

*one coupler can meet all connection requirement

*Manufactured under ISO 9001 standard and same strict quality guarantee.Tested by third party.

*Full traceability of raw material and production batch.

*Tested under several cyclic situation

*No bar conjunction problem happen.

*No large quantity of bars required.

*It can pass below test :

0.5 million times -coupler fatigue test,

1.5 million times-coupler fatigue test,

2 million times-coupler fatigue test,

3.5 million times-coupler fatigue test, coupler fatigue test

Three steps

1. Cutting

one end of reinforcing bar is cutting sawn square

2.Cold forging

The sawn end of rebar is enlarged by a patented cold forging machine, the core diameter of the bar is increased to a pre-determined diameter.

3.Threading

At last , make thread on the end of bar which has been enlarged.

Comparison of upset forging technique

1.Left one is parent rebar , right one is bar cross sectional area after cold forging

2. Left one is cross sectional area of parent bar.

Right one is the rebar thread cross sectional area after cold forging, which is larger or equal to parent bar

* Upset forging the end of bar play the role of a mechanical extrusion , so the molecular structure is tighter , strength surpass the parent bar, increase the strength value in the tensile.

*The thread cross section area after cold forging is not less than parent bar , the area with thrust surface is larger or equal to the parent bar during the tensile test , so the strength of larger than parent bar.

Upset forging parallel thread connection is the best accepted connection way in the world, also the highest quality connection technology in rebar mechanical splicing, 100% higher than 1.1 to 1.3 times of parent rebar, bear the ultimate test 100% break on the bar outside coupler.

The left one is the thread cross section area after upset forging .

The right one is the thread cross section area after rib peel rolling Mechanical test : 100% break on the bar outside coupler

Matched upset forging parallel thread connection——Coupler

We JBCZ factory produce upset forging parallel thread coupler , the standard type is from 12mm to 40mm, also manufacture 50mm,55mm,60mm superior large size according to client’s request.

The coupler specification table , we can customize according to client's request.

Outer Diameter of coupler(mm) | Inner diameter of coupler(mm) | Length of coupler(mm) | Dimension of thread(mm) | |

12 | 20 | 11.9 | 30 | M14*2.0 |

14 | 22 | 13.9 | 34 | M16*2.0 |

16 | 26 | 17.4 | 40 | M20*2.5 |

18 | 29 | 19.4 | 44 | M22*2.5 |

20 | 32 | 20.9 | 48 | M24*3.0 |

22 | 36 | 23.9 | 52 | M27*3.0 |

25 | 40 | 26.3 | 60 | M30*3.5 |

28 | 44.5 | 29.3 | 66 | M33*3.5 |

32 | 50 | 31.8 | 72 | M36*4.0 |

36 | 56 | 34.8 | 80 | M39*4.0 |

40 | 62 | 40.3 | 90 | M45*4.0 |

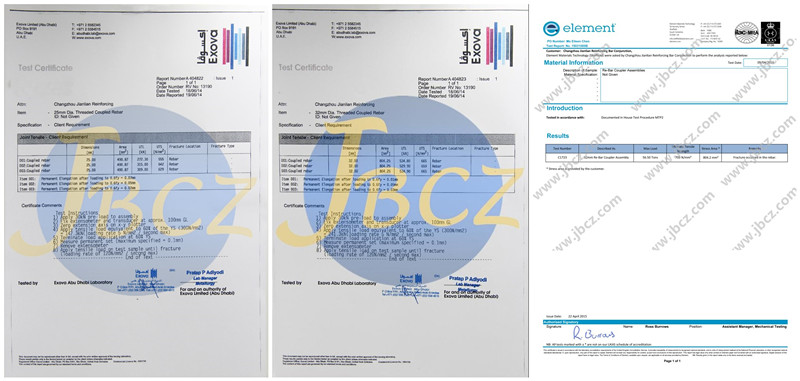

Test Report

Matched upset forging parallel thread—Rebar thread processing machine

*Standard upset forging parallel thread processing machine.

JBGD --150 JBGZL -45

*CE Certificated upset forging parallel threading machine

*Semi automatic upset forging parallel threading machine

*Large power upset forging parallel threading machine

*Automatic European upset forging parallel threading machine

Project application

Our products can applied to bridge rebar splice, Nuclear power engineering rebar splice, Seawater desalination rebar connection, LNG project rebar splice, Metro rebar connection, High tower rebar connection, Viaduct rebar connection and etc.

Different connection method

2》Adding length connection

3》Right and left thread connection

4》Reducing connection

5》Weldable connection

6》Adjustable connection

7》Epoxy reinforcing bar connection

8》Terminal embedded bar connection

9》Bar connection with big chamfering

1. Upset forging parallel thread coupler quality

800Mpa super strength coupler connection White shinning type coupler Big chamfering coupler

Right and left thread type coupler adding length thread coupler Reducing coupler

(rebar cage butt joint when both (both bars can't be rotated) (Connect two bars with different size)

bars can’t be rotated)

Embedded terminal coupler weldable coupler epoxy protection anti corrosion coupler

The coupler production stream line that we have

America ACI-318 standard production line

CNC production workshop

CNC chamfering machine

CNC cutting machine

Chinese JGJ107-2010 standard production line

Thread process tapping machine

1:1 make sure the coupler are centre align , manual chamfering machine , CNC cutting machine

Coupler test steps

1. Purchase raw material specified steel factory to produce steel pipe inspect the surface of each batch of raw material before receiving

Inspect the inner hole for each batch Test the hardness for each batch Test the chemical component for each batch , also do the tensile test for each batch of raw material color marked for storing each batch

2. Qualified production Record the products quantity and scrapped quantity for each production step inspect for each 15 pcs coupler by operators

workshop routing inspection per hour , Casual inspection by workshop director each two hours QC director do the casual inspection before storing each day

Warehouse director do the inspection for coupler each day

3. All couplers have the serial number , or client’s customized mark , there is traceability from raw material’s number , heat number , batch number to the production worker’s code of each step , time of putting in storage , delivery time and arriving time , client’s inspection , start time of using the couplers, etc.

We have test facilities:

100T tensile test machine with computer

in labortary test machine for hardness Eddy Current Instrument Spectrum mineral analyzer

Go and not go gauge Thread ring gauge Vernier Caliper Ball for testing chamfering 100% bar break during tensile test

Connection methods :

Parallel thread standard splice

Easy connection by bar rotation until full thread engagement . Parallel thread : no risk of thread mis-match. No risk of cross-threading.

Adding length splice

Even when both bars can’t be rotated, use a JBCZ standard coupler . The coupler is fully engaged onto the extended thread of the connecting bar.

The assembly is simply completed by butting the bars end to end and screwing back the coupler onto the first bar until full engagement.

Bridging splice

When the end of reinforcing bar can’t be closed (such as the situation happened during producing rebar cage) , JBCZ bridging splice is the method to solve this problem. Two ends of bar are threaded to the standard length , then a ( bridging connection equipment ) is used to connect two reinforcing bars.

Reducing connection

When connect two bars with different diameters , in most situations , can reduce the rebar size with big diameter , then use standard coupler to connect it . But we recommend special reducing coupler , to avoid the difficult task of planning in advance the need of reducing couplers.

Terminal connection

It is a convenient alternative to hooked bars to provide end anchorages in congested areas. JBCZ standard anchorage heads are circular and have a net bearing area of 4 times or 9 times the cross-section of the bar.

Weldable couplers

For composite construction where concrete reinforcement bars must be welded to structural steel , use JBCZ weldable couplers, which are specially made from low carbon steel and which have a large chamfer for bevel welding.